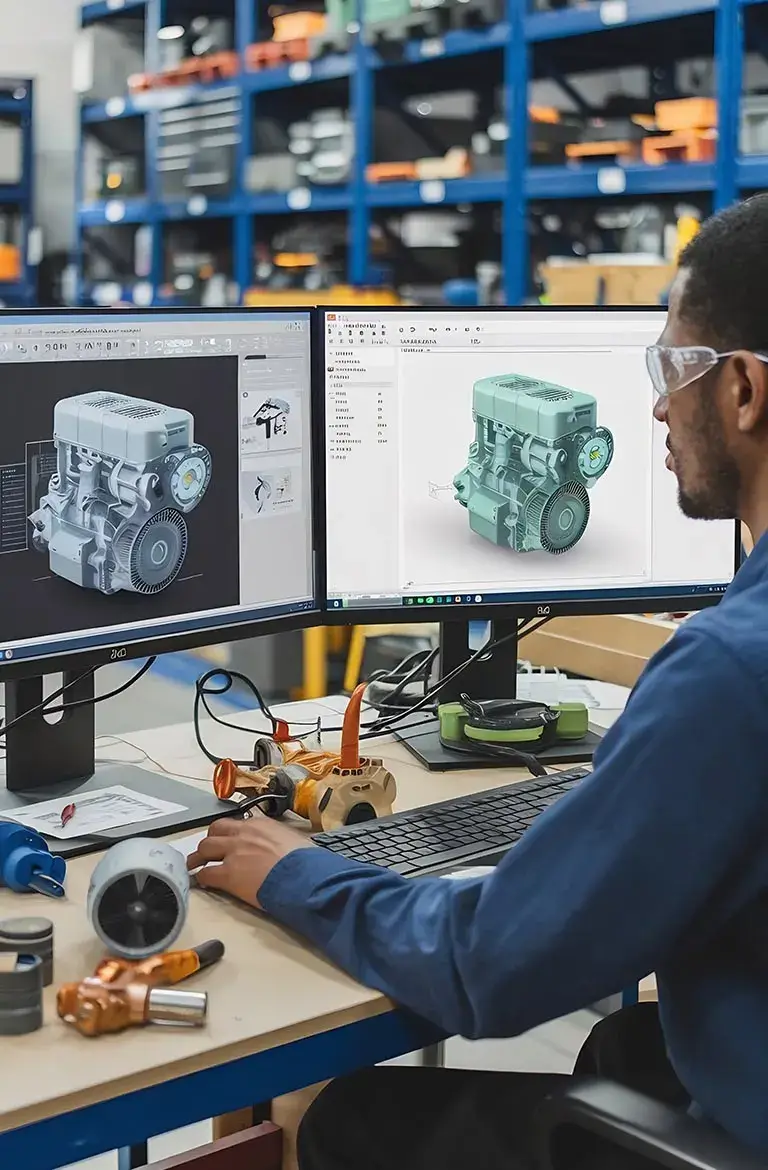

Advanced Simulation & Validation

Engineering decisions are strongest when they are backed by physics, not assumptions. Advanced simulation allows teams to understand how designs will behave before anything is fabricated or deployed in the field—reducing risk, avoiding costly rework, and improving confidence in performance.

At Seashore, we use high-fidelity, physics-based simulation as a design tool, not just a final check. By modeling real operating conditions—including peak and extreme loads—we help teams predict behavior, identify failure risks early, and refine designs for safety, reliability, and compliance long before hardware is built.

Why Simulation-Driven Engineering Matters ?

Simulation plays a critical role in modern product development when used correctly. It helps teams:

- Reduce physical prototyping and late-stage rework

- Identify potential failure modes early in the design process

- Improve safety margins and extend service life

- Support certification, audits, and code compliance

- Enable lighter, more efficient, and better-optimized designs