Manufacturing, Prototyping & Sourcing

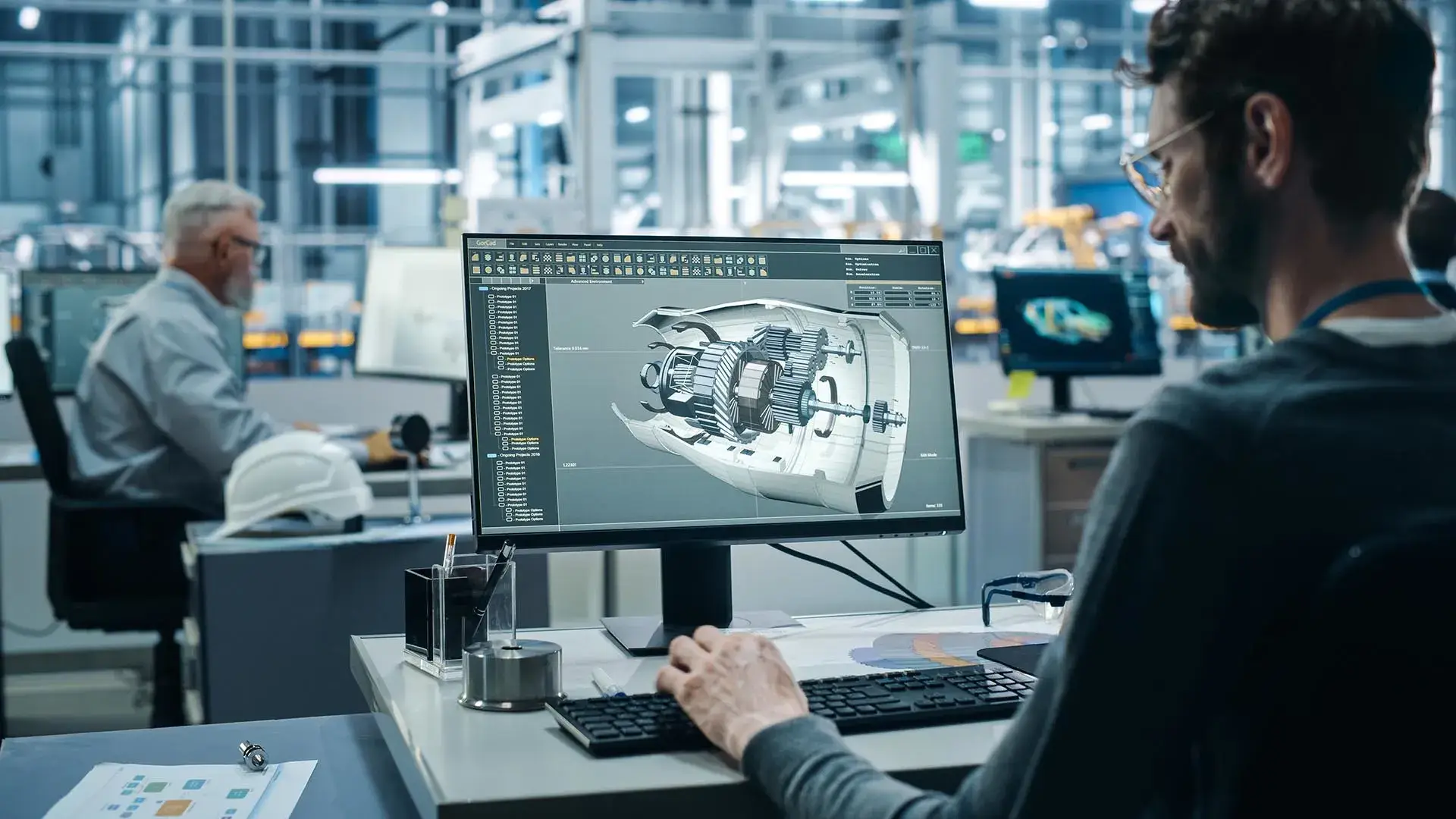

Bringing a design to life requires more than good drawings. It requires a clear connection between engineering intent and how parts are actually built, inspected, and delivered. Manufacturing, prototyping, and sourcing sit at that critical intersection—where ideas become physical products.

At Seashore, we help teams move from prototype to production with confidence. By closely aligning design, fabrication, inspection, and supplier coordination, we reduce risk early, preserve design intent on the shop floor, and support a smooth transition into scalable production.

Why Manufacturing, Prototyping & Sourcing Matter

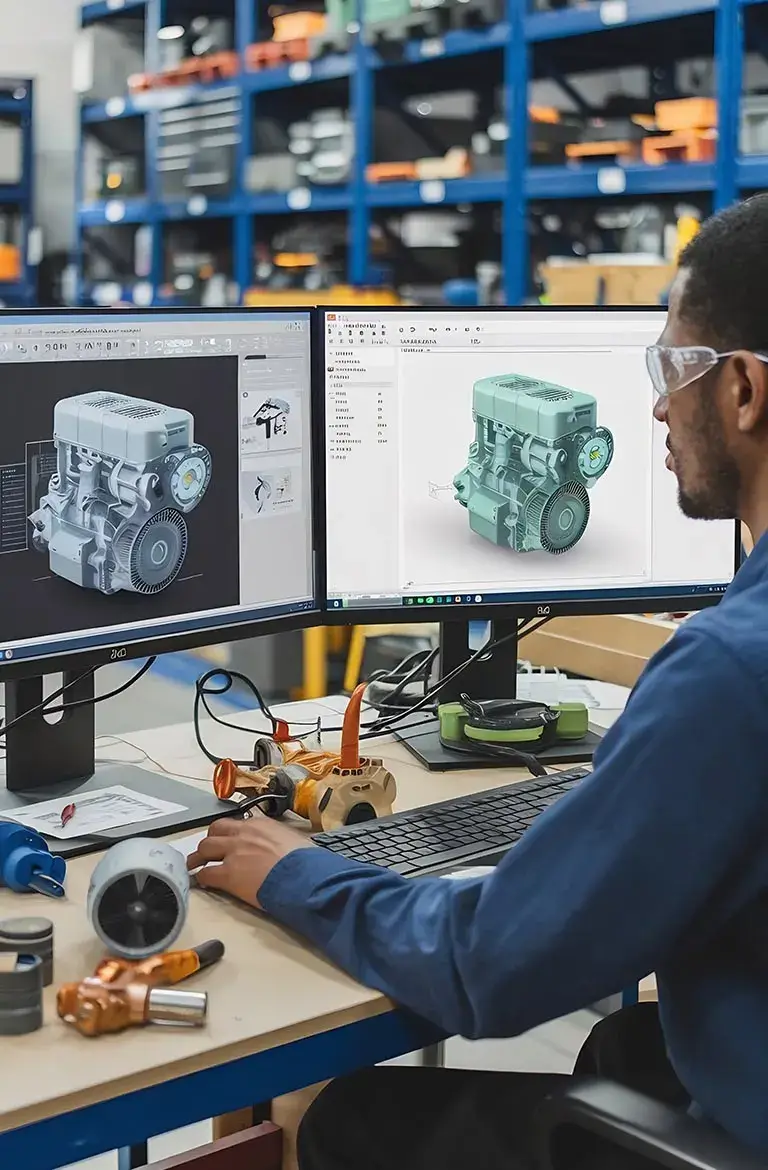

Early manufacturing decisions have a lasting impact on cost, quality, and delivery. A structured approach helps teams:

- Reduce risk during prototyping and early production

- Ensure designs are built as intended, not reinterpreted

- Improve manufacturability, repeatability, and yield

- Strengthen quality control and material traceability

- Shorten the path from development to full-scale production