- Home

-

Services

- Modelling and Drafting

- Migration & Reverse Engineering

- Machine Design & Development

- Product & Value Engineering

- Remote Engineering Staffing

- Advanced Simulation & Validation

- Structural & Heavy Engineering

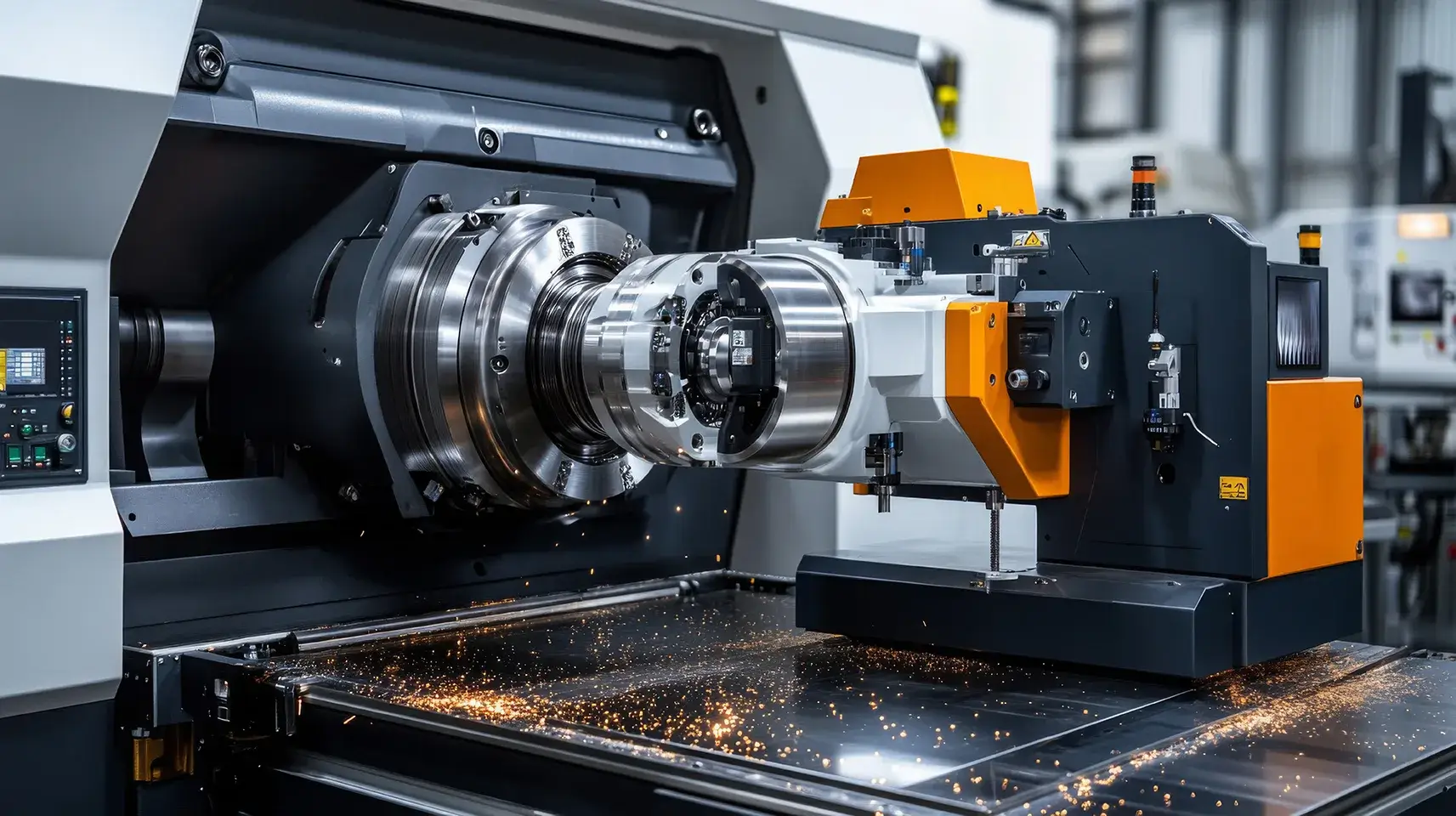

- Manufacturing, Prototyping & Sourcing

- CAD Automation & Customization

- DriveWorks Design Automation

- Industries

- About Us

- Contact Us

☰